|

| |

How to mill out Depron on F3P models

On light-weight models made of Depron there is a significant weight-saving

potential by milling out the Depron in selected areas. It is a quite easy

process, the steps below explains how I have done it.

|

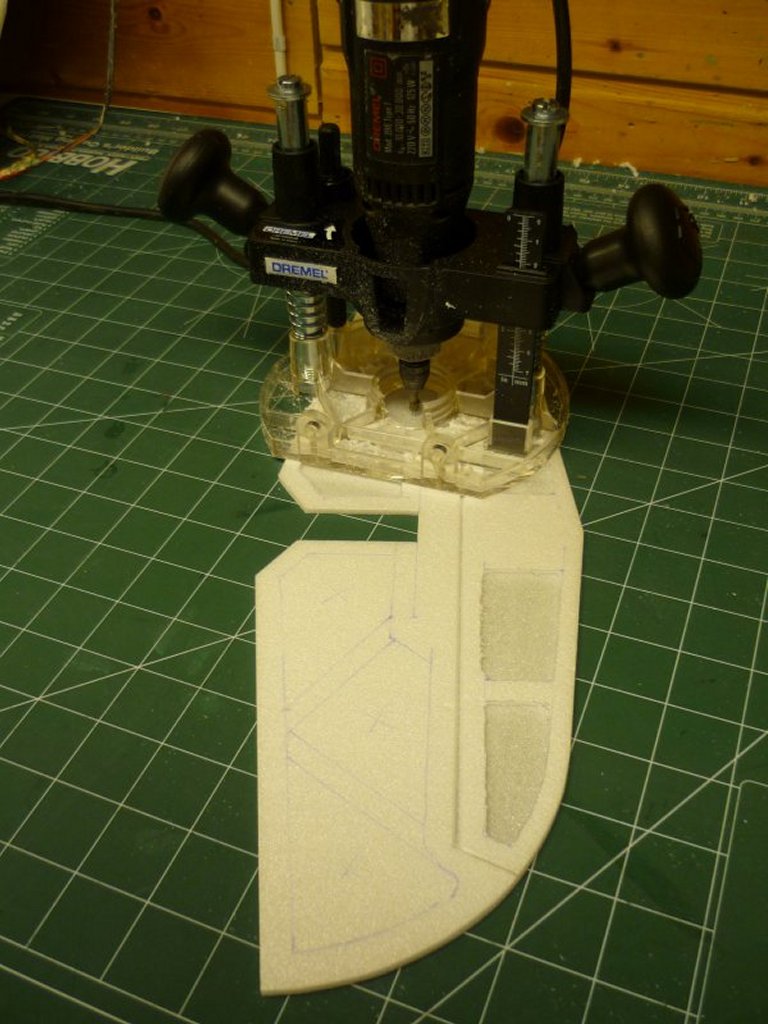

First of all you will need a milling machine, I had an old

and battered Dremel laying around and bought a milling unit to fit.

It's quite cheap. |

|

Then you need a milling tool. I had a Dremel type 196

in my tool-box and have used it, the bigger diameter #115 is probably

better. |

|

For professional use you will need a set of forms to mill

after. For hobby use it's quite OK to draw directly onto the Depron with a

pen and do the milling free-hand. For best result, start in the middle of

the area to mill and move outwards by moving the mill in clockwise

direction |

|

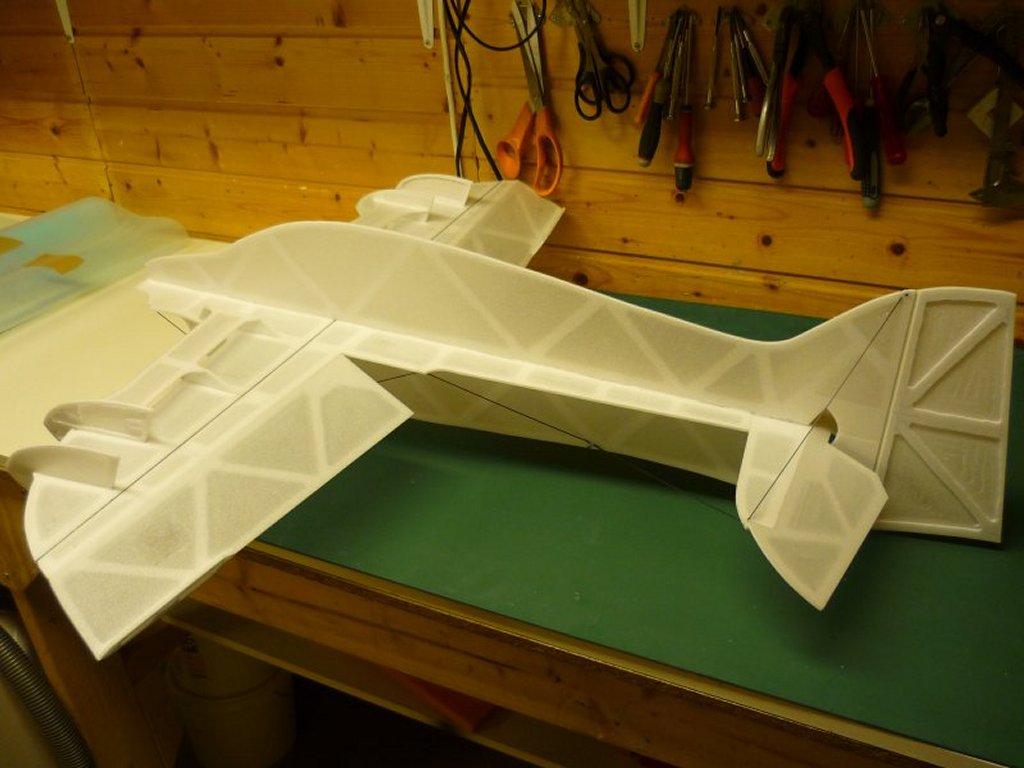

The assembled milled test-model, a Morback. All the

Depron before milling weighed 53.3g, after milling it was down to

34.8g. Assembled without any equipment as it is in the picture it

was 47.5g. |

|